Carina West Processing Facility

state-of-art almond processing

site size & investment

The facility occupies 100 acres and was commissioned in 2008 with an investment of $40 million, highlighting its scale and strategic importance.

processing capacity

The hulling and shelling capacity of 50,000 metric tonnes per annum, enabling efficient handling of large almond volumes during peak season.

large scale – high volumes

storage infrastructure

The scale and layout of the Carina West almond processing facility is a strategic market advantage.

Large Scale – High Volumes

Facilities, Systems & Workforce

Efficient Processing

Our state-of-the-art farming and processing systems allow for efficient handling, grading, and storage of almonds to preserve freshness and uniformity. We work with accredited processors and logistic partners to meet the specifications and timelines required by our global clients.

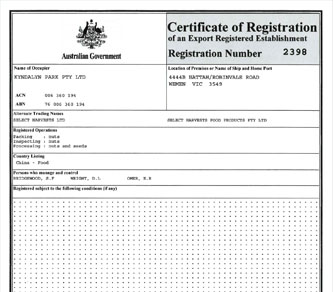

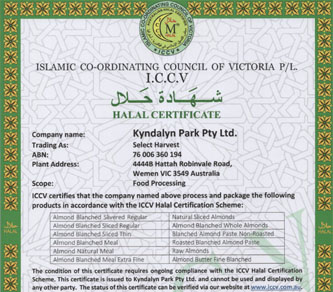

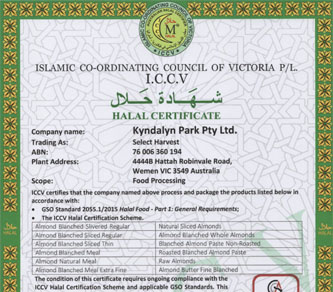

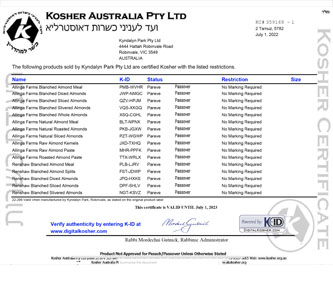

processing certifications

Select Harvests is committed to maintaining the very best standards of producing, processing and distributing almonds.